06

October

The Future of Robotics and Automation in Manufacturing

October 6, 2023

In Blog

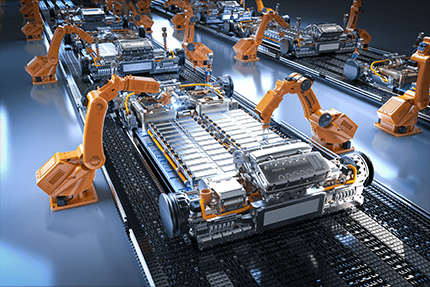

From mechanized looms of the Industrial Revolution to industrial automation solutions and robotics of the 21st century – the manufacturing world continues to grow significantly. New automated technologies not only shape the production of goods but also provide insight into the potential of humans. Manufacturing is becoming more technology-dependent than ever. As we stand on the edge of new industrial innovations, it’s important to explore the future of robotics and automation.

The Current Scenario

The current world of automation and robotics in factories is coexistence and transformation. Manufacturers adopt and embrace technologies for improved quality, efficiency, and production. With customization and a flexible approach towards recognizing their potential, the systems come with AI that can change with the client’s needs and wants. A Manufacturing Operations Management (MOM) system makes the entire manufacturing process simpler and more efficient. AI algorithms control maintenance, production, quality, and decision-making. Robots are working alongside humans to pick, place, pack, and assemble products. They make the work easier and offer precision and accuracy in tasks. Automation and robotics in manufacturing are thriving and will continue to evolve.

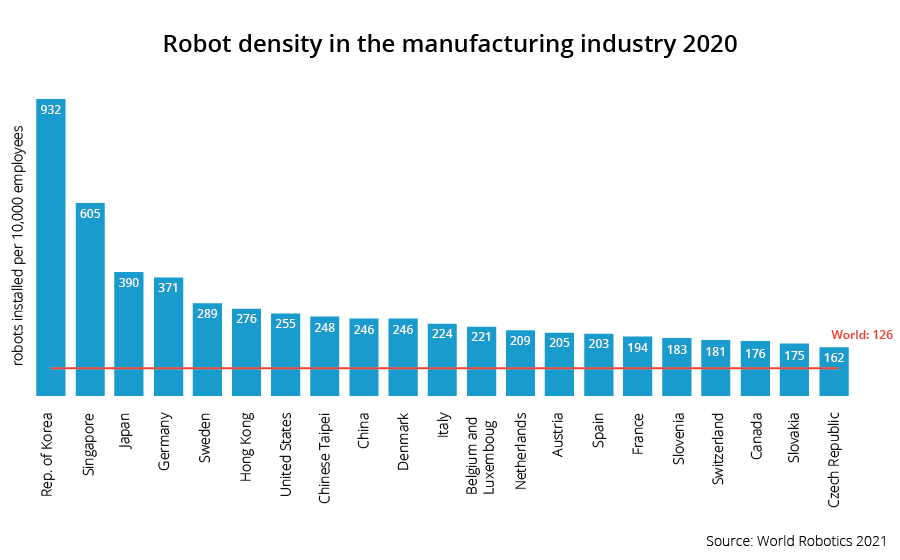

Robotics Usage Around the World

The use of industrial robots in manufacturing factories around the globe is increasing rapidly. As per the 2021 World Robot report, 126 robots are being deployed per 10,000 manufacturing employees, roughly double the amount jusfive years back.

As per Milton Guerry, President of the International Federation of Robotics, robot density is the barometer to track the degree of automation adoption in the manufacturing industry worldwide. The graphic below shows robot density in different regions of the manufacturing industry in 2020.

Robotics and Automation – Pros and Cons

It’s important to understand the pros and cons of robotics and automation to understand how it can help your own situation.

Pros

- Enhanced efficiency: Automation and robotics help to produce goods efficiently with faster production, reduced lead time, and a steady rise in output. It reduces the need for human interaction and minimizes errors.

- Quality control: Automated codes function to take real-time aspects, analyze the data, and change accordingly. A manufacturing automation system helps to achieve excellent product quality.

- Expense reduction: A manufacturer saves overtime when they switch to automation and robotics. Even with a high initial price, lower labor and energy costs help you save in the future.

- Round-the-clock operations: Automated machines and robots do not need breaks or shifts, unlike human operators. They can function 24 x 7 at a defined rate to complete orders without delays.

- Enhanced safety: Workers dodge dangerous tasks prone to accidents with automation and robots. Robotic process automation software protects workers without hampering the production process.

- Precise and accurate: Machines have fewer errors than humans as they work with higher accuracy and precision for greater quality and fewer defects.

- Higher production: With high efficiency, speed also increases. Manufacturers can set the production speed, and robots can work at a faster rate to meet an increase in demand.

- Flexibility: Automation processes and robots are easy to program and reprogram as needed. They adapt very quickly to different tasks.

- Higher profits: Robotics and automation machinery manufacturing lead to an increased production of goods. It boosts profitability by improving quality, consistency, and market adaptability.

- Reduced waste: Automation and robots help with the tactical use of resources and reduce waste production. With a calculative use of resources, modern aids help cut costs and result in better savings.

Cons

- Job displacement: Many skilled laborers are losing their position in the industry with the advent of automation and robots. It not only replaces them but can destroy their livelihood.

- Initial costs: The primary expense of introducing industrial automation solutions and robots in manufacturing is high. However, it provides a return on investment, but the time to achieve it varies for different manufacturers.

- Technology and skill: Humans have control even when machines perform tasks. A skilled team that understands automated processes and robots is critical.

Smart Factory MOM

The eWorkplace Manufacturing, Inc. Smart Factory is a leading MOM solution that empowers manufacturing operations. Smart Factory MOM helps with consistency, efficiency, and quality.

- Efficiency: It enhances the overall equipment efficiency. With it, the production cycle time decreases and the production and performance of your manufacturing unit increases.

- Quality: A high-quality product is not a concern for the manufacturer anymore. With low defects and wastage reduction, Smart Factory MOM helps with client satisfaction.

- Timeliness: If deadlines concern you, our MOM solution will help to ensure you meet them. Smart Factory functions accurately to deliver products before deadlines for smoother trade.

- Resourcefulness: Our automation in manufacturing solution caters to optimum resource use. It reduces wastage and utilizes raw materials to their fullest potential.

- Labor productivity: The Smart Factory MOM allows you to use your workforce to its full potential. It assigns tasks according to their skills and knowledge for increased productivity.

- Asset utilization: From coordinating production to monitoring equipment performance, Smart Factory collects real-time data and analyses it. As a result, it can maximize asset efficiency and reduce operational costs.

- Real-time analysis: It uses real-time analysis by continuously monitoring market data and performance metrics. It further adjusts and optimizes to enhance productivity and quality.

- Remote monitoring and control: Automation machinery manufacturing lets you oversee processes from off-site locations. It allows for control interfaces, decision-making, troubleshooting, etc.

- Availability: Smart Factory MOM functions even when you are away. It is a reliable and trustworthy solution that automates manufacturing 24/7.

See the Power of Smart Factory MOM in

Action: Schedule Your Demo Now

Future Advancements

The growth of robotics in factories and automation will continue. Technology is advancing in many ways that helps manufacturers achieve more operational efficiency.

Artificial Intelligence

Artificial intelligence is a growing technology that plays a significant role in manufacturing. Its advent into automation and robots improves the analysis of data, autonomous decisions, adaptability, and flexibility. It optimizes the entire production process with less human assistance.

Collaborative Robots (Cobots)

Cobots will become more prevalent and work alongside humans to enhance productivity and ensure safety. These manufacturing robots are functional and adaptable in every way to fit the needs of the manufacturing world.

Flexibility and Customization

The systems in current use are already flexible and can produce custom goods. But with time, the ability to be flexible and adapt quicker will increase significantly. Automation software will cater to changing client demands more efficiently.

5G

The ultra-low latency, high bandwidth, and network capabilities of 5G is helpful for automation and robotics in factories. Its real-time response for data-intense applications will allow for increased efficiency. It will be capable of greater speed and reliable connectivity for manufacturing needs.

Internet of Things (IoT) Connectivity

The IoT is already in use and provides seamless connectivity. It enables real-time data exchange and predictive maintenance. It will also further increase production efficiency and the ability to plan production more effectively to meet changing market dynamics.

3D printing

The blend of 3D printing with manufacturing robots and automation will create a new path for a technological revolution. It will have the ability to create rapid prototypes, reduce waste, and create complex designs. It will also be capable of customizing parts and offering solutions for immediate defect handling.

Robotics and automation integration in manufacturing is yielding many benefits. It is shifting how industries operate. With time, they will redefine the nature of work and innovation and will help drive economic growth. Embracing the future with responsible use of automation will help manufacturers be successful.

The transformation of the manufacturing industry with robotic process automation software isn’t without challenges, but it promises to continue to change the industry. Trustworthy MOMs like Smart Factory facilitates customization and flexibility in manufacturing. It combines human creativity and problem-solving with the consistency of machines and automation.

Robots and automation integration into the manufacturing industry is a transformative force. They enhance efficiency, productivity and offer safer working environments. Manufacturers that effectively harness these technologies will effectively compete as things evolve.

Contact us today to learn more about how we can help you implement, train, and maintain the Smart Factory MOM solution and count on us to help you overcome any hurdles along the way.