A Glimpse into Lean Manufacturing

A Glimpse Into Six Sigma

The Significance of Lean Manufacturing and Six Sigma in MOM

Waste Minimization: Both lean manufacturing and Six Sigma help reduce waste and costs. A MOM system can help you eliminate eight crucial forms of waste including transport, inventory, motion, waiting, overproduction, over processing, defects, and underutilized skills.

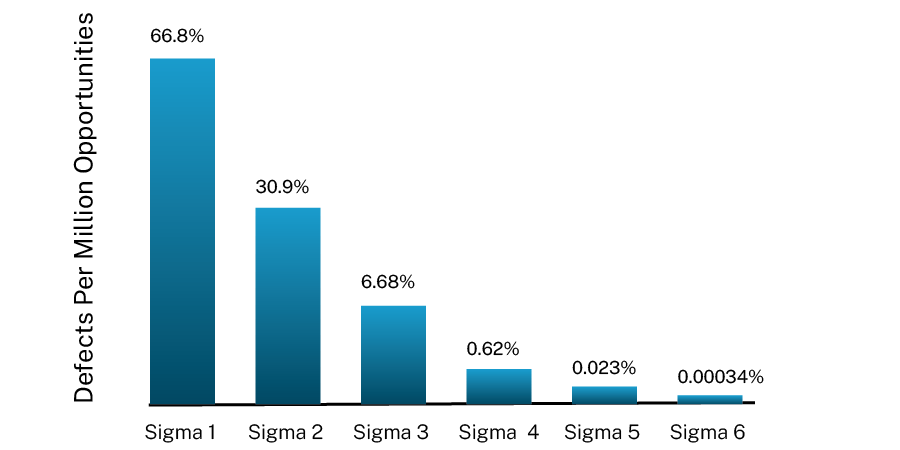

- Quality Improvement: Embracing these techniques will infuse quality in your products to meet or even exceed customer expectations. This will enhance your customer satisfaction and company’s reputation. With MOM, you can achieve a sigma level of 6, equating to only 3.4 defects per million.

- Continuous Adaptation: The market trends and needs keep changing and only those businesses will succeed that can keep pace with such dynamics. Again, both these concepts are based on improvements, especially in changing scenarios. As MOM operations continue to evolve, adapt to changing markets with our expertise.

Understanding the Terminology

Define

Clearly define crucial aspects such as the problem, goals, scope, key stakeholders, and other relevant input.

Measure

Collect data and create relevant baseline performance metrics. This helps quantify the ongoing situation and identify the scope for improvement.

Analyze

Analyzing the collected data determines the root causes of defects, poor quality, inefficiencies, etc. Tools like Pareto charts and more can help here

Improve

Upon analysis and knowing improvement areas, develop solutions to uproot problems. Implement and evaluate the effectiveness of necessary fine-tuning.

Control

Things change which require a keen control mechanism to modify processes. Always monitor systems to prevent the recurrence of defects using KPIs.

Smart Factory’s MOM Solution and its Capabilities

- Resource Optimization:With our Remote Monitoring and Control system, you can optimize resources, including raw materials, manpower, and machinery. It offers cost savings, increased efficiency, and improved resource efficiency.

- Effective Decisions: The Smart Factory MOM system uses real-time data that provides valuable insights to make informed decisions, plan strategically, and execute effectively. With accurate data at your fingertips, it’s easy to respond more quickly and precisely.

- Risk Mitigation: Only those who can foresee risks and act accordingly will emerge as winners in this competitive industry. Our advanced MOM solution identifies and mitigates risks associated with manufacturing processes to minimize costly disruptions and product recalls.

- Customer-Centric: We understand that each company’s manufacturing units have unique needs. Our Smart Factory MOM solution is customer-centric and designed by experts in the manufacturing. We prioritize customer satisfaction and align our techniques with your manufacturing processes.

- Sustainability-driven: Environmental awareness and the desire for sustainable practices has increased. Our team focuses on offering lean manufacturing and Six Sigma capabilities that help to reduce waste, conserve energy, and reduce harmful emissions.