- Functionalities

- Industries

- Services

- Resources

-

-

- Manufacturing Knowledge Base

- What is Smart Factory?

- What is Manufacturing Operations Management (MOM)?

- What is a Manufacturing Execution System (MES)?

- What is Production Scheduling in Manufacturing?

- WHAT IS ADVANCED PLANNING AND SCHEDULING (APS)?

- What Is OEE in Manufacturing and How Can It Be Improved?

- WHAT IS CONNECTED MANUFACTURING (IIoT)?

- Manufacturing Knowledge Base

-

-

- Company

- Schedule demo

Best in Class Smart

Factory Software

Drive Growth and Efficiency with Smart Manufacturing Software Solutions

Take a leap forward to modern manufacturing with Smart Factory Software enabling an interconnected network of machines, creates an intelligent manufacturing ecosystem with IIoT, AI, and data analytics capabilities supporting the industry 4.0 revolution. It connects machines, people, and processes to share information and offers enhanced productivity with predictive maintenance, advanced scheduling, workflow optimization, and more.

With Smart Factory MOM, manufacturers can capture real-time data and analyze the information, leading to better decision-making and operational efficiency. This cutting-edge manufacturing software solution gives manufacturers tools to optimize factory operations and maintain a competitive edge.

Automate manufacturing operations with Smart Factory MOM, a comprehensive manufacturing software suite including MES, Advanced scheduling, workforce management, reports & analytics, and more, backed with IIOT and AI technology.

Smart Factory MOM Functionalities: Innovative and Comprehensive Digital Manufacturing Solutions

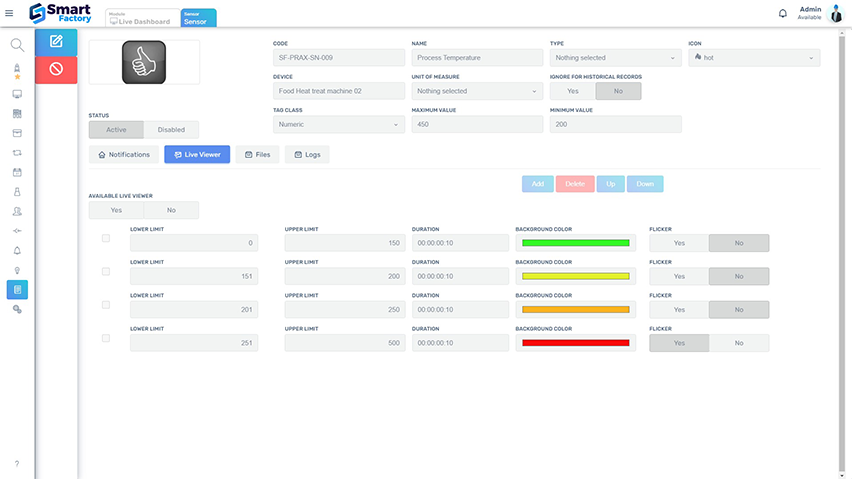

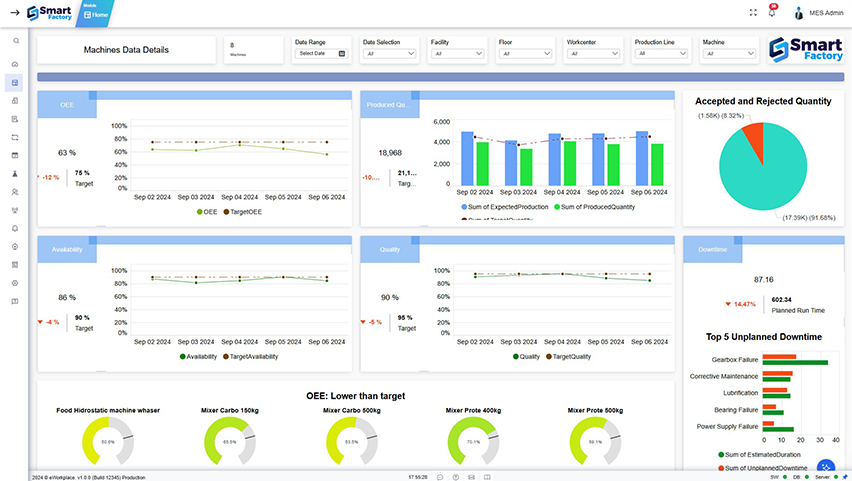

Smart Factory combines IoT data reading, real-time dashboards, OEE (Overall Equipment Effectiveness) tracking, add-on reports, production scheduling, MES (Manufacturing Execution System), Asset Management, and Workforce Management to optimize your manufacturing operations.

Learn More

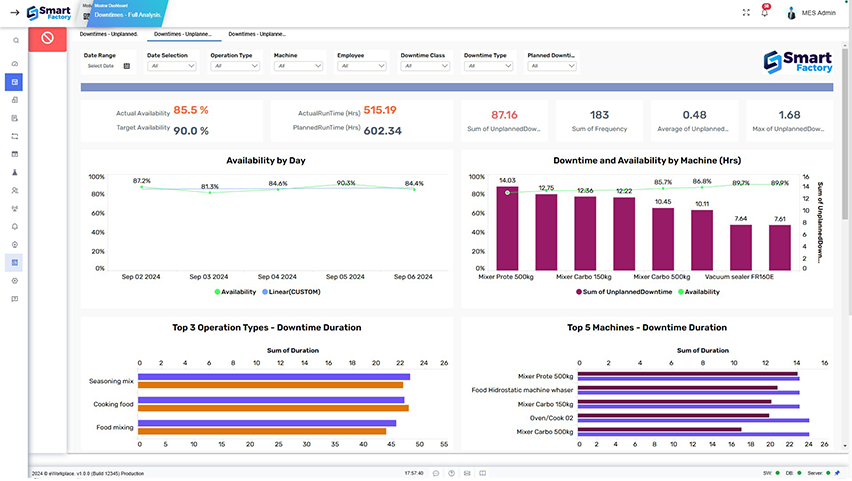

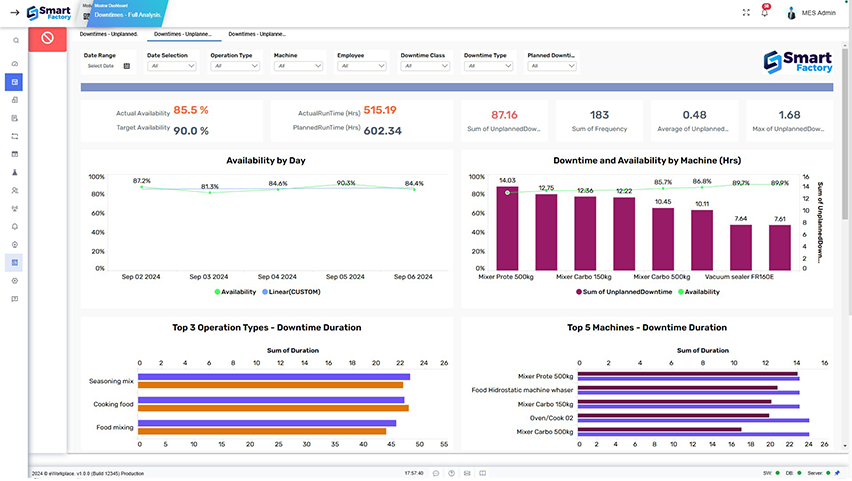

With Smart Factory Analytics, you can monitor your factory's performance in real-time, identify bottlenecks, and make data-driven decisions to improve efficiency. Our OEE tracking feature allows you measure and optimize machine and production line performance, with add-on reports for quick issue resolution.

Learn More

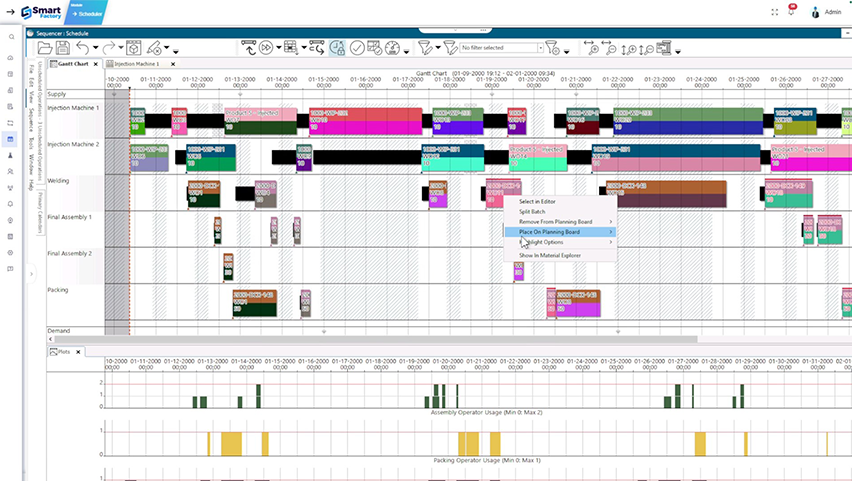

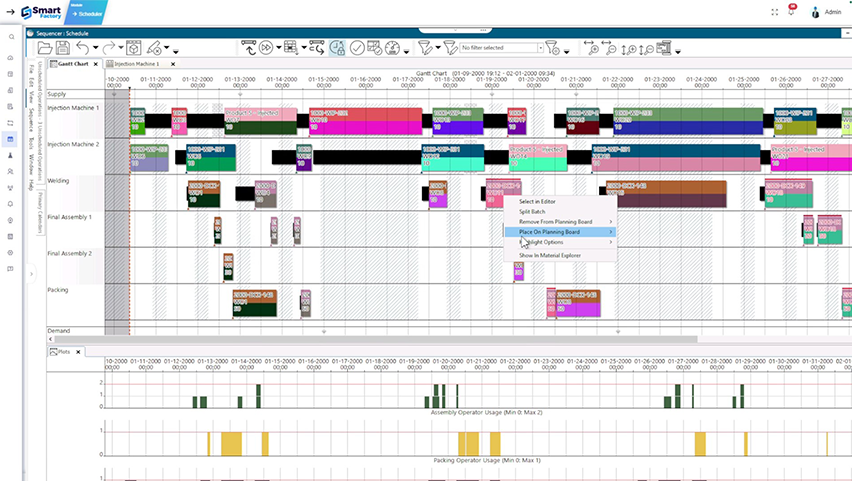

Our production scheduling feature ensures that your resources are optimized, orders are delivered on time, and idle is minimized.

Learn More

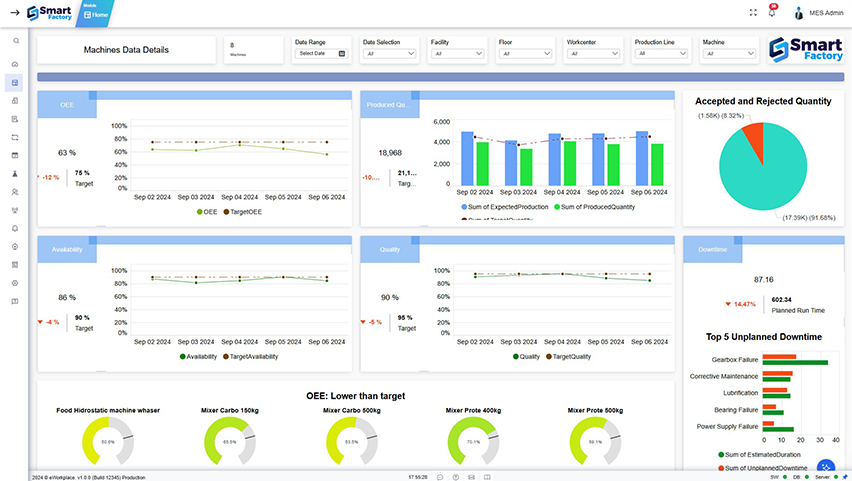

Our OEE (Overall Equipment Efficiency) module offers dynamic calculation and traceability with real-time visualization. Fully integrated with production modules, IIoT, and control panels, it allows for perfect performance monitoring.

Learn More

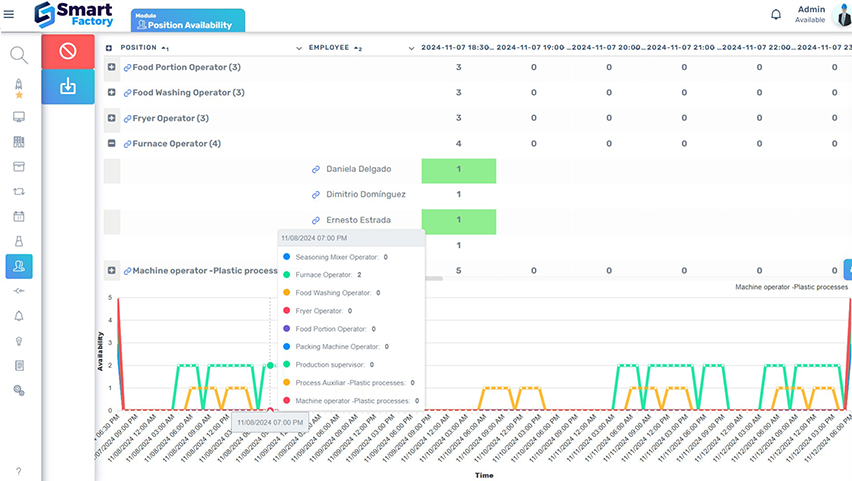

You can also efficiently manage your assets, track their performance, and streamline your workforce with our intuitive Workforce Management tools.

Learn More

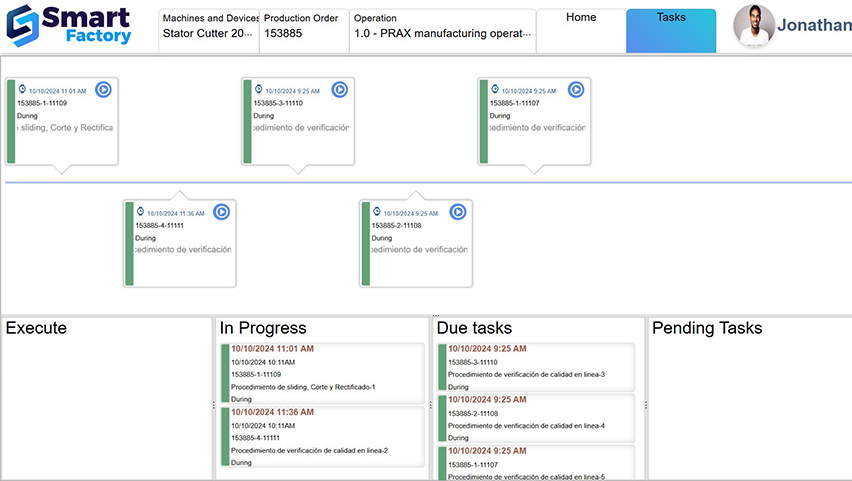

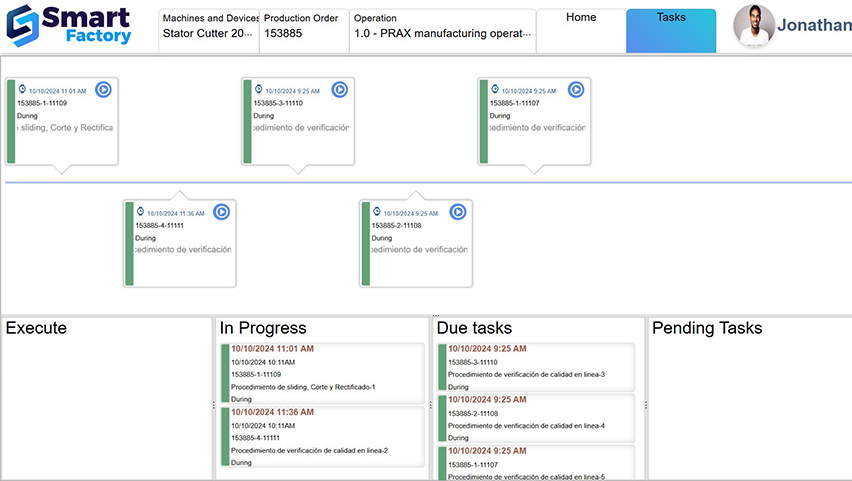

Smart Factory MOM e-SOPs (electronic standard operating procedures) provide you with guided execution while supporting dynamic transactions. With our SOPs and their capabilities, users (operators) can follow digitalized workflows, with real-time traceability of any step executed.

Learn More

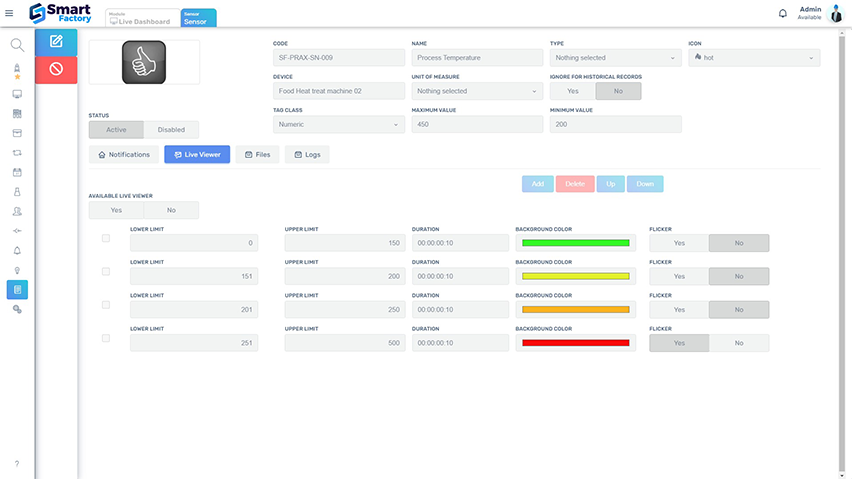

IOT

Smart Factory combines IoT data reading, real-time dashboards, OEE (Overall Equipment Effectiveness) tracking, add-on reports, production scheduling, MES (Manufacturing Execution System), Asset Management, and Workforce Management to optimize your manufacturing operations.

Learn More

Analytics

With Smart Factory Analytics, you can monitor your factory's performance in real-time, identify bottlenecks, and make data-driven decisions to improve efficiency. Our OEE tracking feature allows you measure and optimize machine and production line performance, with add-on reports for quick issue resolution.

Learn More

Scheduling

Our production scheduling feature ensures that your resources are optimized, orders are delivered on time, and idle is minimized.

Learn More

OEE

Our OEE (Overall Equipment Efficiency) module offers dynamic calculation and traceability with real-time visualization. Fully integrated with production modules, IIoT, and control panels, it allows for perfect performance monitoring.

Learn More

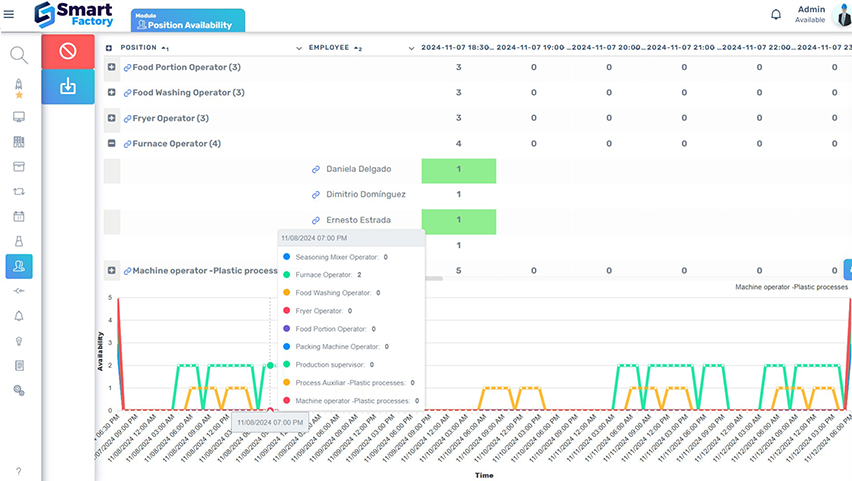

Workforce

You can also efficiently manage your assets, track their performance, and streamline your workforce with our intuitive Workforce Management tools.

Learn More

OMS

Smart Factory MOM e-SOPs (electronic standard operating procedures) provide you with guided execution while supporting dynamic transactions. With our SOPs and their capabilities, users (operators) can follow digitalized workflows, with real-time traceability of any step executed.

Learn MoreSmart Factory MOM Across Industries: Tailored for Your Needs

Explore how Smart Factory can revolutionize your operations, visit our industry-specific pages to discover how our web application can help you unlock new levels of efficiency, productivity, and competitiveness in your industry. Learn more about our tailored solutions for your specific industry and see how Smart Factory can transform your manufacturing processes.

Process Manufacturing

Discrete Manufacturing

Smart Factory Software’s Benefits

Improved Overall Equipment Efficiency (OEE), leading to increased equipment productivity and performance.

Increased production output and reduced cycle times, resulting in higher manufacturing efficiency and productivity.

Reduced downtime and increased uptime, improving equipment reliability and availability.

Enhanced product quality and yield rates, reducing waste and improving customer satisfaction.

Optimized labor productivity, leading to better workforce utilization and increased production efficiency.

Improved asset utilization, resulting in higher efficiency and effectiveness of production assets.

Higher on-time delivery rates, leading to improved customer satisfaction and increased customer loyalty.

Cost reduction through decreased material waste, reduced downtime, and optimized resource utilization.

Enhanced real-time visibility into production processes, leading to better decision-making and responsiveness to production issues.

Driving Operational Excellence with Smart Factory MOM Software

10-20%Increased Production Efficiency

With Smart Factory, you can expect a reduction in production cycle times, resulting in higher throughput and increased output.

20-40%Enhanced Quality and Compliance

Smart Factory helps improve product quality and compliance, leading to a reduction in defects and non-conformances.

10-20%Enhanced Labor Productivity

Smart Factory helps optimize workforce management, potentially improving labor productivity.

15-30%Reduced Scrap and Rework

With Smart Factory, you can expect a reduction in scrap and rework costs by identifying and addressing process inefficiencies.

We help you to select the best option

Ready to optimize your manufacturing operations? Download the Smart Factory Buyer’s Guide now and discover how our cloud-based solution can help you streamline production, improve efficiency, and boost competitiveness.

Smart Factory Machine Connectivity

Smart Factory’s machine connectivity can benefit small and mid-sized manufacturers by enabling real-time data collection, remote monitoring and control, improved productivity, enhanced visibility, and better-quality control, leading to improved operational efficiency and competitiveness.

Real-time data collection

Machine connectivity enables real-time data collection from equipment, providing insights for monitoring and decision-making.

Remote monitoring and control

Machine connectivity enables remote management of production processes, improving operational efficiency and agility.

Improved productivity

Machine connectivity automates data capture, reducing manual tasks, and providing accurate data for analysis.

Enhanced visibility

Machine connectivity provides real-time visibility into production processes for better decision-making and issue resolution.

Smart Factory Pillars

A modular approach makes Smart Factory a flexible solution that allows for a phased deployment of its comprehensive capabilities. From scheduling and shop floor management to visibility of online and offline devices and resource performance management including machines, employees, and tooling – Smart Factory brings it all together to provide valuable insights into your operations through embedded role-oriented reports and dashboards. With its simple-to-use interface, yet robust, secure, and scalable architecture, Smart Factory empowers you to optimize your operations, improve efficiency, and boost productivity.

Smart Factory Insights

How to Create Manufacturing Work Instructions: A Comprehensive Guide with Real-Time Example

Manufacturing work instructions are the backbone of consistent and safe production. They guide operators through each task with clear steps, visuals, safety notes, and quality checkpoints, making complex processes easier to execute and repeat. This blog explains what manufacturing work instructions are, how to create them, their utility across the shop floor, and the comparison between paper and digital formats. Also, the process for creating work instructions is illustrated with a real-time example to show what a well-structured instruction looks like in practice.

Learn moreNew

How to Create SOP in Manufacturing? Explained with a Real-Time Example

The current industrial landscape is undoubtedly challenging, as in any business, regardless of its nature, aspects such as accuracy, consistency, and efficiency are considered non-negotiable. Achieving these three areas and, at the same time, achieving a goal can be a complex task without the right tools in action.

Learn moreNew

Difference Between Takt Time, Cycle Time, and Lead Time: A Smart Factory Perspective

In the world of manufacturing, it is common to mistakenly use concepts that may be associated with the same topic or root, even though they refer to different principles. That is the case of Takt time, Cycle time and lead time.

Learn moreNew

Advanced Guide to Calculating Takt Time: Formula, Challenges, Benefits, and More

Takt time is the rate at which a product must be completed to meet customer demand. It considered rhythm, and in the field of production and manufacturing it is applied to represent the maximum time allowed to produce a unit of a product to satisfy customer demand.

Learn more

An Advanced Guide to Changeover Time: Formula, Examples, and Best Practices

Changeover time is a crucial indicator in manufacturing, indicating the time necessary to move a production line or production equipment from one product to another.

Learn more

A Guide to Manufacturing Downtime and Reducing Costs

A Guide to Manufacturing Downtime and Reducing Costs In the manufacturing industry, time is equivalent to money. Efficiency is the primary requirement in this sector, where even a slight production delay of a few minutes can have a significant financial impact. This throws light on the concept of “downtime”—a period of inactivity or non-production that […]

Learn more

Discover how our cutting-edge Smart Factory solution can transform your business. Contact us today!